Hot rolling and cold drawing process of seamless steel tube

Release time:

2024-01-04 15:02

When it comes to seamless steel pipe, the first thing that comes to mind is that the quality of this pipe (Conduit) material is superior, which is the characteristic of seamless steel pipe. Secondly, the seamless steel pipe adopts the structure of steel (Structure), so the hardness (Hardness) of seamless steel pipe is very high. Seamless steel pipe is to make the molten metal and iron substrate reaction to produce alloy layer, so that the substrate and the plating layer are combined. Hot galvanizing is to pickle the steel pipe first, in order to remove the iron oxide on the surface of the steel pipe, after pickling, it is cleaned by ammonium chloride or zinc chloride aqueous solution or ammonium chloride and zinc chloride mixed aqueous solution tank, and then sent to the hot dip plating tank. Hot galvanizing has the advantages of uniform coating, strong adhesion and long service life. The quality of seamless steel pipe is the reason why this pipe material can be promoted and developed in the industrial field (domain), which is determined by the complex production (Produce) process (production engineering) of seamless steel pipe. The characteristic of seamless steel pipe is that there is no joint in the wall part, while the ordinary pipe has obvious joints.

Single from the process (technology) point of view (angle) to consider (consider), the general seamless steel pipe production (Produce) process can be divided into cold drawn and hot rolled two. Steel pipes are widely used in construction, machinery, coal mines, chemicals, electric power, railway vehicles, automobile industry, highways, bridges, containers, sports facilities, agricultural machinery, petroleum machinery, prospecting machinery and other manufacturing industries. At present, seamless steel pipe manufacturers in the market use nothing more than these two methods to manufacture (zhìzào). In comparison, the production process of cold-rolled seamless steel pipe is generally more complicated than hot rolling. Annealing (annealing) process is a very important step (procedure), must use acid (Acerbity) liquid pickling, if in this process (process) there is a lot of foaming, then the quality (Mass) can not reach the corresponding standard.

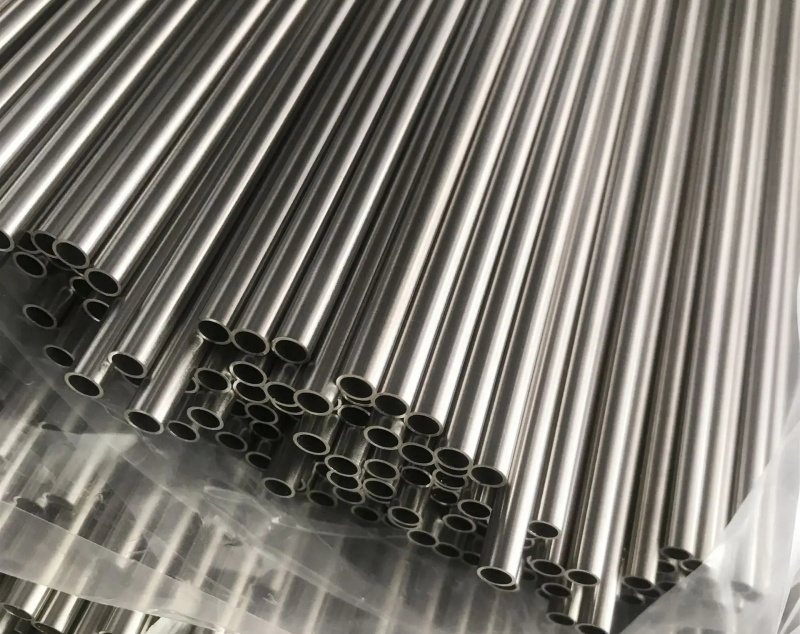

The appearance of cold rolled seamless steel pipe seamless steel pipe is shorter than the hot rolled seamless steel pipe seamless steel pipe, cold rolled seamless steel pipe wall thickness is generally smaller than the hot rolled seamless steel pipe, but the surface looks brighter than the thick wall seamless steel pipe, the surface is not too rough, the diameter is not too much burr. Steel pipes are widely used in construction, machinery, coal mines, chemicals, electric power, railway vehicles, automobile industry, highways, bridges, containers, sports facilities, agricultural machinery, petroleum machinery, prospecting machinery and other manufacturing industries. Buyers are often based on specific needs to choose the appropriate seamless steel pipe, use (use) of the field (domain) is different, the need for seamless steel pipe in the type and material (The material) also has a certain difference, on the whole, this pipe material (Material) is more in the cost-effective advantage.

Previous article

News