What factors affect the performance of heat exchanger seamless steel tube?

Release time:

2023-11-20 13:43

What factors affect the performance of heat exchanger seamless steel tube?

The performance of heat exchanger seamless steel pipe is affected by many factors, including the following aspects:

Material selection: The material selection of the seamless steel pipe of the heat exchanger is an important factor affecting the performance. Common materials are carbon steel, alloy steel, stainless steel and so on. Different materials have different chemical compositions and mechanical properties. For different working conditions and media, it is necessary to select suitable materials to ensure performance.

Steel pipe wall thickness: The wall thickness of the seamless steel pipe of the heat exchanger directly affects its pressure resistance and corrosion resistance. If the wall thickness is too thin, the strength of the steel pipe may be insufficient, and it is prone to rupture or deformation; if the wall thickness is too thick, it will increase the cost of the steel pipe and also increase the resistance of the fluid flow. Therefore, the wall thickness of the steel pipe must be moderate to meet the pressure and corrosion resistance requirements under working conditions.

Surface treatment: The surface treatment of the seamless steel pipe of the heat exchanger is very important for its performance. Common surface treatment methods are pickling, shot peening, polishing and so on. The surface treatment is mainly to remove impurities such as scale and rust on the surface of the steel pipe, improve the corrosion resistance and lubricity of the steel pipe, and also help to improve the heat transfer efficiency.

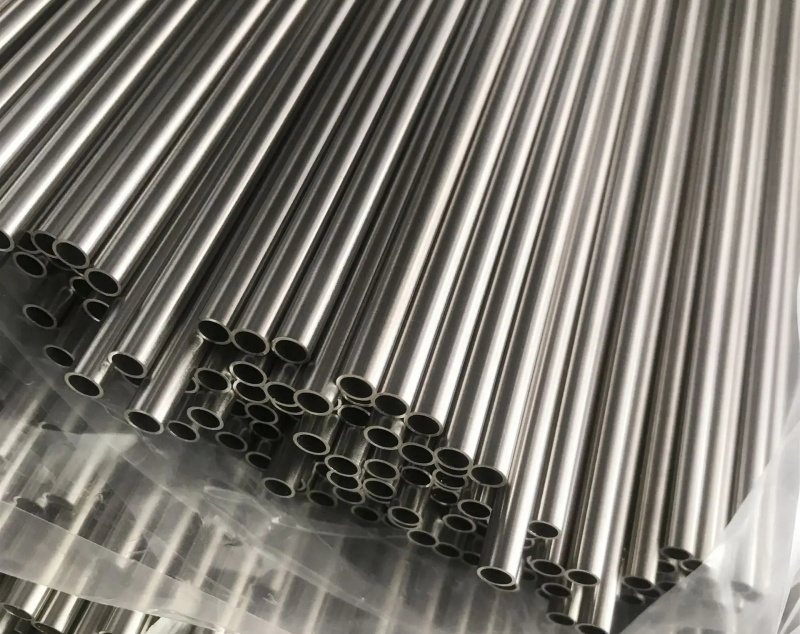

Heat exchanger steel pipe

Pipe connection: Seamless steel pipes often need to be connected in heat exchangers. The choice of connection method also has an impact on performance. Common connection methods include welding, threaded connection, and ferrule connection. Welded connections can provide better strength and sealing, but may affect the corrosion resistance of the steel pipe; while threaded connections and ferrule connections are relatively easy to disassemble and repair, but their connection strength and sealing may be poor. Choosing a suitable connection method requires comprehensive consideration of the convenience of installation and maintenance, the requirements under working conditions, and the characteristics of the material.

Temperature and pressure: The seamless steel pipe of the heat exchanger will be affected by high temperature and high pressure during the working process, which will have a significant impact on its performance. High temperature will cause thermal expansion, creep and oxidation of steel pipes, resulting in material deformation and oxidation corrosion; high pressure will produce pressure and stress on steel pipes, which may cause bending, deformation and cracking. Therefore, the selection of suitable materials and appropriate steel pipe wall thickness, as well as the necessary heat treatment and surface treatment, can improve the high temperature and high pressure resistance of the steel pipe.

In summary, the performance of seamless steel tubes for heat exchangers is affected by many factors. In the selection of materials, determine the wall thickness, surface treatment, select the appropriate connection and control process and manufacturing quality, it is necessary to consider the working conditions and requirements, as well as the material characteristics of the steel pipe, to ensure the excellent performance of the heat exchanger seamless steel pipe.

Previous article

Next article

Previous article

Next article

News